We are introducing a new state-of-the-art controlled cooling system to improve our aluminium casting process.

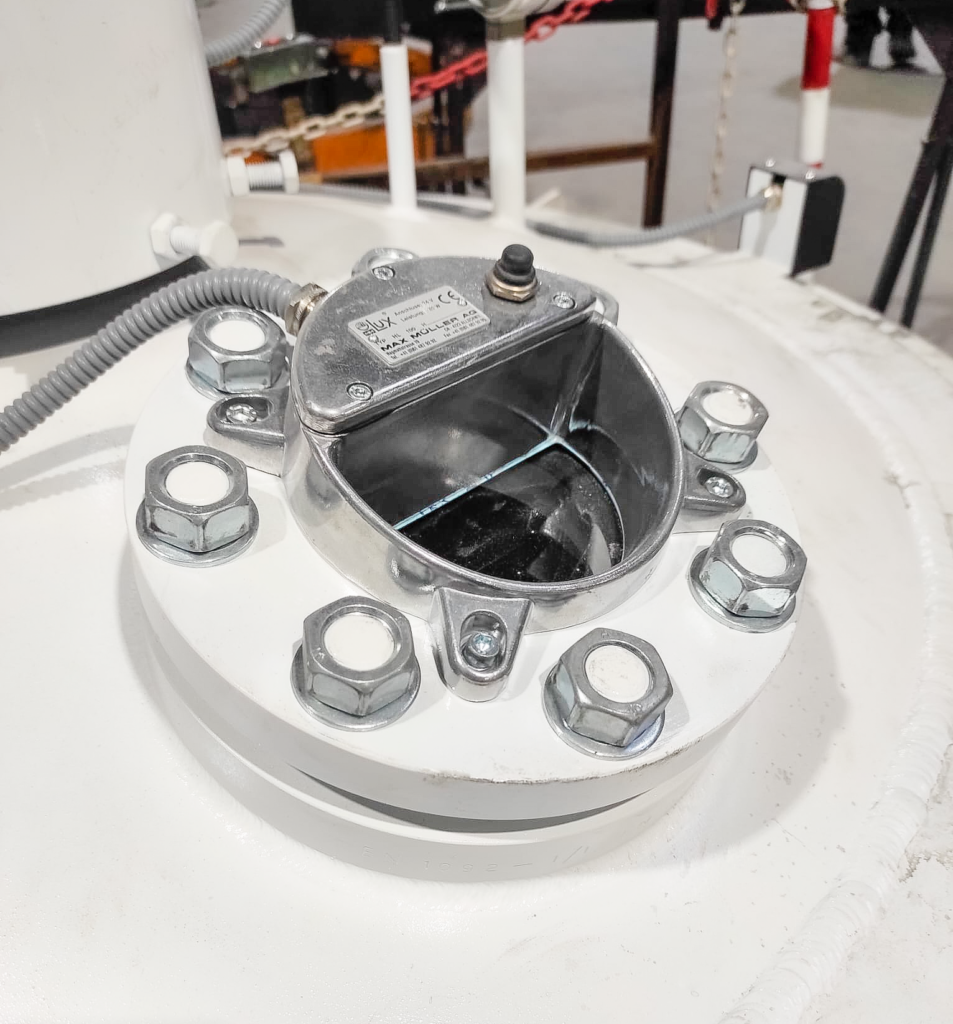

We are currently finalising the installation of the new High Performance Sensorised Cooling equipment for Aluminium Casting. A correct in-mould part cooling is a keystone in the aluminium casting process.

For this reason, EIPC Research Center has developed, in collaboration with ATTSU KLAUS, a new CONTROLLED COOLING SYSTEM to maximise the efficiency of this process.

With an investment of 65.000 Euros, the new installation will allow us to manufacture products with better mechanical properties, as well as to increase our production capacity by 30% in the manufacture of high performance aluminium parts. The investment in this new controlled cooling system equipment has been supported by SPRI’s Industry 4.0 Renove Programme.

This commitment reinforces EIPC’s leading position in terms of innovation and investment in new technologies, and responds to the growing demand from our customers for products of greater complexity and high mechanical requirements.

The improvement of our aluminium casting capabilities will ensure greater production efficiency. This movement is a key step in keeping EIPC Group at the forefront of the investment casting industry.